RS-35kV Strengthened Matrix Heat-shrinkable Pipe

Made of radiation crosslinking polyolefin material, it has excellent physical, chemical and electrical properties. It is suitable for insulation protection of 35kV bus with voltage level and busbar of high voltage equipment. It can effectively shorten the minimum safe distance between systems.

¡¾Product characteristics ¡¿

Implementation criteria: DL/T1059-2007

Heat shrinkage ratio: 2:1

Low Smoke, Soft, Flame Retardant, High Strength,

Electric Carbon Mark Resistance

Shrinkage temperature: 84¡æ~120¡æ

Low voltage switch cabinet £º-55¡æ~125¡æ

Environmental protection standard £ºRoHS

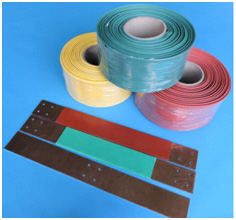

Standard colours: red, yellow and green. Other

colours can be customized

¡¾Technical index¡¿

|

performance |

index |

Test methods/conditions |

|

tensile strength |

¨R8.0Mpa |

ASTM D2671 |

|

elongation at break |

¨R300% |

ASTM D2671 |

|

Tensile mild after thermal aging |

¨R6.9Mpa |

130¡æ*168h |

|

Fracture elongation rate after thermal aging |

¨R100% |

130¡æ*168h |

|

Axial change rate |

¨R-8%~+8% |

ASTM D2671 |

|

Oxygen index |

¨R30 |

GB/T 2406 |

|

thermal shock |

No crack |

JB 7829 Appendices D |

|

Breakdown strength |

¨R20kV/mm |

ASTM D149 |

|

hardness |

¨Q90 |

GB2411 |

|

Volumetric resistivity |

¨R1014 Ω.cm |

IEC 60093 |

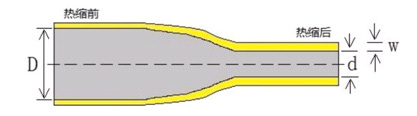

Structural sketch

Specification table

|

Specifications |

Supply inner diameter D(mm) |

Full shrinkage size (mm) |

Standard packaging |

|

|

|

|

internal diameter d |

wall thickness w |

Rice / plate |

|

§¶30/15 |

¨R30 |

¨Q15 |

¨R3.70 |

15 |

|

§¶40/20 |

¨R40 |

¨Q20 |

¨R3.70 |

15 |

|

§¶50/25 |

¨R50 |

¨Q25 |

¨R3.70 |

15 |

|

§¶65/33 |

¨R65 |

¨Q33 |

¨R3.70 |

15 |

|

§¶75/38 |

¨R75 |

¨Q38 |

¨R3.70 |

15 |

|

§¶85/43 |

¨R85 |

¨Q43 |

¨R3.70 |

15 |

|

§¶100/50 |

¨R100 |

¨Q50 |

¨R3.70 |

15 |

|

§¶120/60 |

¨R120 |

¨Q60 |

¨R3.70 |

15 |

|

§¶150/75 |

¨R150 |

¨Q75 |

¨R3.70 |

15 |

|

§¶180/90 |

¨R180 |

¨Q90 |

¨R3.70 |

15 |

|

§¶210/105 |

¨R210 |

¨Q105 |

¨R3.70 |

15 |

|

§¶230/115 |

¨R230 |

¨Q115 |

¨R3.70 |

15 |

|

§¶250/125 |

¨R250 |

¨Q125 |

¨R3.70 |

15 |

|

§¶300/150 |

¨R300 |

¨Q150 |

¨R3.70 |

15 |

RS-20kV Matrix heat-shrinkable tube

It is made of radiation crosslinked polyethylene hydrocarbon material and has excellent physical, chemical and electrical properties. It is suitable for insulation protection of medium and high voltage switchgear cabinet, indoor foreign exchange bus and busbar of medium and high voltage equipment.

¡¾Product characteristics¡¿

Executive standard £ºDL/T1059-2007

Heat shrinkage ratio: 2:1

Low Smoke, Soft, Flame Retardant, High Strength,

Electric Carbon Mark Resistance

Shrinkage temperature£º84¡æ~120¡æ

Service temperature £º-55¡æ~125¡æ

Environmental protection standard £ºRoHS

Standard colours: red, yellow and green. Other

colours can be customized

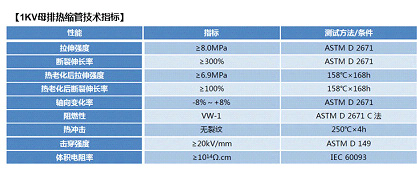

¡¾Technical index¡¿

|

performance |

index |

Test methods/conditions |

|

tensile strength |

¨R8.0Mpa |

ASTM D2671 |

|

elongation at break |

¨R300% |

ASTM D2671 |

|

Tensile mild after thermal aging |

¨R6.9Mpa |

130¡æ*168h |

|

Fracture elongation rate after thermal aging |

¨R100% |

130¡æ*168h |

|

Axial change rate |

¨R-8%~+8% |

ASTM D2671 |

|

Oxygen index |

¨R30 |

GB/T 2406 |

|

thermal shock |

No crack |

JB 7829 Appendices D |

|

Breakdown strength |

¨R20kV/mm |

ASTM D149 |

|

hardness |

¨Q90 |

GB2411 |

|

Volumetric resistivity |

¨R1014 Ω.cm |

IEC 60093 |

Structural sketch

Specification table

|

Specifications |

Supply inner diameter D(mm) |

Full shrinkage size (mm) |

Standard packaging |

|

|

|

|

internal diameter d |

wall thickness w |

Rice / plate |

|

§¶15/7.5 |

¨R15 |

¨Q7.5 |

¨R2.0 |

25 |

|

§¶20/10 |

¨R20 |

¨Q10 |

¨R2.0 |

25 |

|

§¶25/12.5 |

¨R25 |

¨Q12.5 |

¨R2.0 |

25 |

|

§¶30/15 |

¨R30 |

¨Q15 |

¨R2.0 |

25 |

|

§¶40/20 |

¨R40 |

¨Q20 |

¨R2.2 |

25 |

|

§¶50/25 |

¨R50 |

¨Q25 |

¨R2.2 |

25 |

|

§¶60/30 |

¨R60 |

¨Q30 |

¨R2.2 |

25 |

|

§¶65/32.5 |

¨R65 |

¨Q32.5 |

¨R2.2 |

25 |

|

§¶70/35 |

¨R70 |

¨Q35 |

¨R2.2 |

25 |

|

§¶75/37.5 |

¨R75 |

¨Q37.5 |

¨R2.2 |

25 |

|

§¶80/40 |

¨R80 |

¨Q40.0 |

¨R2.2 |

25 |

|

§¶85/42.5 |

¨R85 |

¨Q42.5 |

¨R2.2 |

25 |

|

§¶100/50 |

¨R100 |

¨Q50.0 |

¨R2.2 |

25 |

|

§¶120/60 |

¨R120 |

¨Q60.0 |

¨R2.2 |

25 |

|

§¶150/75 |

¨R150 |

¨Q75.0 |

¨R2.2 |

25 |

|

§¶160/80 |

¨R160 |

¨Q80.0 |

¨R2.2 |

25 |

|

§¶180/90 |

¨R180 |

¨Q90.0 |

¨R2.2 |

25 |

RS-10KV£¨M£©10kV Strengthened Matrix Heat-shrinkable Pipe

¡¾Product introduction¡¿

Made of radiation crosslinked polyolefin material, it has excellent physical, chemical and electrical properties. It is mainly used for insulation protection of busbar in medium and high voltage switchgear, power plant, substation, outdoor or indoor. It can prevent foreign body overlapping, short circuit of small animals, incorrect entry of charged gap by maintenance personnel, prevention of condensation flashover, and increase phase insulation. And so on.

¡¾Product characteristics¡¿

Implementation criteria:DL/T 1059-2007

Heat shrinkage ratio: 2:1

Environmental protection, high strength, good elasticity,

flame retardant, soft

Shrinkage temperature £º84¡æ¡«120¡æ

Service temperature £º-55¡æ¡«125¡æ

Environmental protection standard £ºRoHS

¡¾Technical index¡¿

|

performance |

index |

Test methods/conditions |

|

tensile strength |

¨R10.4Mpa |

ASTM D2671 |

|

elongation at break |

¨R300% |

ASTM D2671 |

|

Tensile mild after thermal aging |

¨R7.3Mpa |

130¡æ*168h |

|

Fracture elongation rate after thermal aging |

¨R100% |

130¡æ*168h |

|

Breakdown strength |

¨R25kV/mm |

GB/T1408.1 |

|

Hardness (Shaw A) |

¨Q90 |

GB2401 |

|

Volumetric resistivity |

¨R1014 Ω.cm |

IEC 60093 |

|

Oxygen index |

¨R30 |

GB/T 2406 |

|

Heat shock resistance |

No crack |

JB 7829 Appendices D |

|

Water absorption rate |

¨Q0.5% |

ISO62-1980 |

|

Power frequency withstand voltage |

¨R30kV.1min |

GB/T14081 |

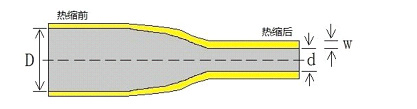

Structure diagram

Specification table

|

Specifications |

Supply inner diameter D(mm) |

Full shrinkage size (mm) |

Standard packaging |

|

|

|

|

internal diameter d |

wall thickness w |

Rice / plate |

|

§¶15/8 |

15+0.8 |

¨Q8 |

2.1+0.30 |

25 |

|

§¶20/10 |

20+0.8 |

¨Q10 |

2.1+0.30 |

25 |

|

§¶25/12.5 |

25+0.8 |

¨Q12.5 |

2.1+0.30 |

25 |

|

§¶30/15 |

30+0.8 |

¨Q15 |

2.1+0.30 |

25 |

|

§¶40/20 |

40+1.0 |

¨Q20 |

2.3+0.30 |

25 |

|

§¶50/25 |

50+2.0 |

¨Q25 |

2.3+0.30 |

25 |

|

§¶60/30 |

60+3.0 |

¨Q30 |

2.3+0.30 |

25 |

|

§¶65/33 |

65+3.0 |

¨Q33 |

2.3+0.30 |

25 |

|

§¶70/35 |

70+3.0 |

¨Q35 |

2.3+0.30 |

25 |

|

§¶75/38 |

75+3.0 |

¨Q38 |

2.3+0.30 |

25 |

|

§¶80/40 |

80+3.0 |

¨Q40.0 |

2.3+0.30 |

25 |

|

§¶85/43 |

85+3.0 |

¨Q43 |

2.4+0.30 |

25 |

|

§¶100/50 |

100+4.0 |

¨Q50 |

2.4+0.30 |

25 |

|

§¶120/60 |

120+4.0 |

¨Q60 |

2.4+0.30 |

25 |

|

§¶150/75 |

150+4.0 |

¨Q75 |

2.4+0.30 |

25 |

|

§¶180/90 |

180+5.0 |

¨Q90 |

2.4+0.30 |

25 |

|

§¶210/105 |

210+5.0 |

¨Q105 |

2.4+0.30 |

25 |

|

§¶230/115 |

230+5.0 |

¨Q115 |

2.4+0.30 |

25 |

|

§¶250/125 |

250+5.0 |

¨Q125 |

2.4+0.30 |

25 |

RS-1kV 1 kV heat-shrinkable tube for mother exhaust

¡¾Product introduction ¡¿

The 1KV heat-shrinkable tube is made of radiation crosslinked polyolefin material with excellent physical, chemical and electrical properties. Its main functions are electrical insulation of connectors, rust and corrosion prevention of solder joints, mechanical protection, reducing phase spacing, etc. It is widely used in the fields of electronics, communications, machinery and manufacturing.

¡¾Product characteristics ¡¿

1¡¢Ö´Ðбê×¼£ºGB/T 1059-2007,

2¡¢Implementation criteria: GB/T 1059-2007,

3¡¢ Low smoke, softness, flame retardant, high strength

and resistance to electric carbon mark¡£

4¡¢Shrinkage Temperature: 84 120 C

5¡¢Service temperature: - 55 ~125 C

6¡¢ Environmental standards: RoHS

7. Standard colours: black, white, red,

yellow, green and blue. Other colours can be customized.

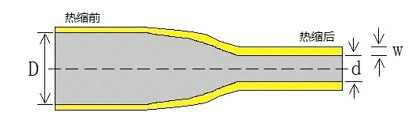

Structural sketch